Author: Vincenzo Piemonte, Associate Professor, University UCBM – Rome (Italy)

1. Theme description

Produced water is typically generated in large quantity for the lifespan of a well. It is made up of natural formation water as well as the uphole return of water injected into the formation as part of an enhanced recovery operation.

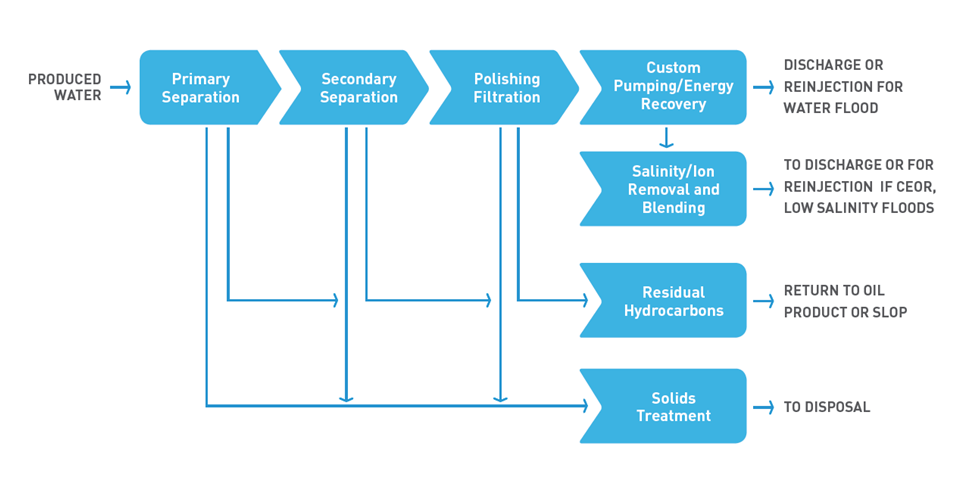

Technologies and strategies applied to produced water comprise (Figure 1):

- (1) Minimization

- (2) Recycle / Re-use

- (3) Disposal

Onshore produced water can be re-injected to provide additional oil and gas recovery, treated and used for civil usage or disposed on the reservoir according to regulations and permits.

Offshore produced water can be re-injected into reservoir, disposed as discharge to the sea after suitable treatment or transported onshore for suitable treatments and subsequent disposal.

Figure 1 – Produced water treatment overview

Nowadays, it has become essential to recover and use this water again due to the more and more stringent environmental limits (the components of produced water must exhibit persistent, toxic or bioaccumulative properties) and the always increasing water demand.

Produced waters are characterized by a high content of salt and oil that render necessary to device a specific treatment train in order to decontaminate them, as for example with respect to a municipal wastewater. Typically, produced water contains high concentrations of aromatic hydrocarbons e.g BTEX (benzene, toluene, ethylbenzene, xylene), NPD (naphthalene, phenanthrene e dibenzotiophene) and PAH (polycyclic aromatic compounds), minerals, radioactive substances, dissolved gases, scale products, waxes, microorganisms and dissolved oxygen [1].

To remove hydrocarbon components from produced water, biological, physical and chemical methods are available. In offshore extraction facilities due to space constraints, compact physical and chemical treatment technologies are preferred such as photo-electrocatalyticprocesses, hydrocyclones, coagulation and flocculation [2]. Most of these techniques are only suitable for pretreatment of wastewater for in situ reuse, e.g. reinjection for enhancing oil recovery [3]. On the contrary, membrane technology may be successfully used to remove hydrocarbons from oil-contaminated wastewater, also in the presence of a high salinity. Membrane processes offer several advantages over conventional treatments such as compact module, lower energy consumption, environmental friendliness and high quality product independently on fluctuations in feed quality. Because of the presence of dissolved and suspended oil in untreated produced water, the membrane equipment may become fouled, thus increasing operation costs [4]. At this purpose, the vibrating membrane technology process VSEP® (Vibratory Shear Enhances Process) is a technology that limits membrane fouling [5].

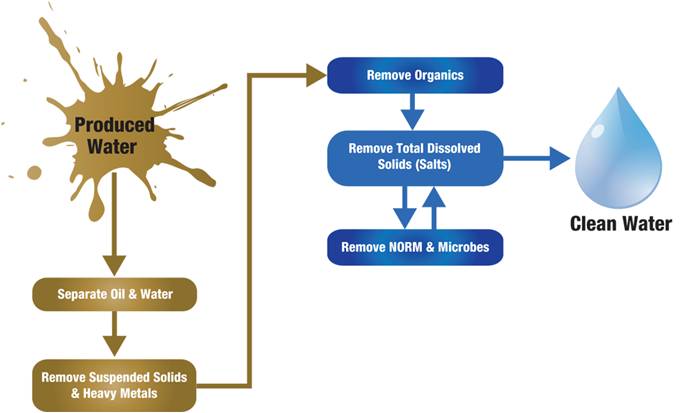

Figure 2 – Produced water treatment steps

Actually, the most important treatments applied to produced water are classified as primary, secondary and tertiary processes. In the following it is possible to find a short description of these processes.

2. Processes

2.1 Primary Treatments

Primary Treatments are mainly devoted to remove suspended hydrocarbons components and solids from produced water. Figure 1 reports the block scheme of the primary processes[6]. The produced water, leaving the three-phase separator which separates oil, gas and water coming from the wellhead, is sent to the gravity separator (API separator), which removes, from water surface, oils and other light fractions with a lower density than water. These fractions, removed by an oil skimmer, are then sent to the oil recovery stage. The settled particles are conveyed on the bottom of the separator and transferred to the oil sludge processing.

The water separated from oil reaches the free surface on the side opposite to the power supply and it is sent to a mixing tank, where appropriate amounts of coagulants and flocculants are added to facilitate the particles coalescence by sedimentation.

Figure 3 – Primary Treatment Scheme

Then, water enters into the dissolved gas flotation (DGF) stage, where nitrogen or natural gas (to avoid explosions upon contact with hydrocarbons) is blown to separate oil, suspended solids and other macromolecules.

The produced water coming from the DGF stage is further deoiled and then sent in another mixing tank, where chemical reagents are added (polyelectrolytes, caustic soda and aluminum chloride); then, the stream is treated in a sedimentation tank to remove metals. Before the secondary treatment stages, produced water passes through sand filters to ensure a further reduction of pollutants.

2.2 Secondary Treatments

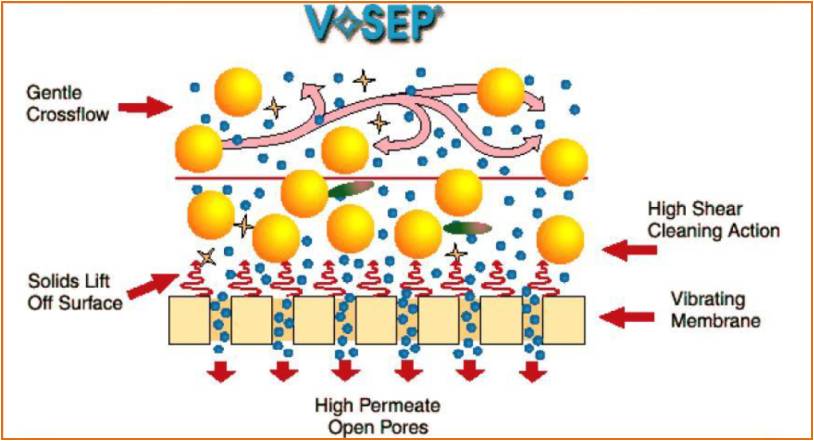

The main “secondary” treatments are known as Best Available Techniques for produced water treatment [7]. These techniques (based on adsorption, biodegradation, stripping, membrane separation) not only allow the removal of organic compounds, suspended solids and oil, but are also able to eliminate the dissolved aromatic hydrocarbons such as BTEX and NPD. It was possible to establish that the treatment with the vibrating membrane system VSEP (Vibratory Shear Enhances Process) turns out to be the best process to be applied to the produced water, managing to get with a single operation an effluent with an extremely high degree of purity without the addiction of any other chemical and without the production of a large amount of waste.

In the VSEP membrane system, patented by New Logic Research, the feed slurry remains nearly stationary, moving in a leisurely, meandering flow between parallel membrane leaf elements. Shear cleaning action is created by vigorously vibrating the leaf elements in a direction tangent to the faces of the membranes: the propagation of shear waves from the sinusoidal membrane surface favors the suspension of particles on it, facilitating the flow, thus reducing the membrane fouling.

Figure 4 – VSEP Membrane scheme

2.3 Tertiary Treatments

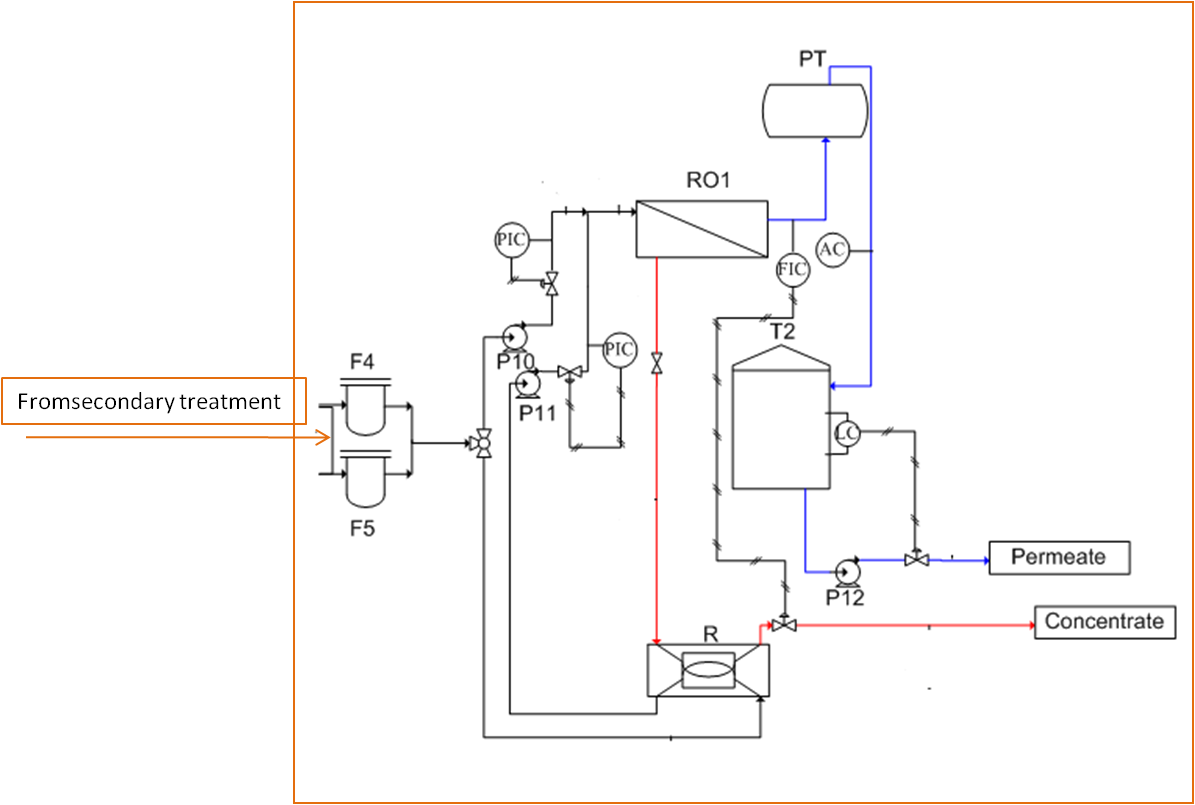

Tertiary treatment are focused on the salts removal from treated produced water coming from secondary processes. By using the reverse osmosis as tertiary treatment [8], mainly reducing the levels of nitrates and phosphates, it is possibleto ensure the necessary attributes required by the law for the reuse of water for industrial and agricultural purposes. Figure 3 shows an example of Reverse Osmosis Process applied to produced water treatment

To prevent precipitation of low soluble salts on the membrane surface, antiscalant and chemicals are added to water in the upstream of reverse osmosis stage. The permeate is then pressurized and sent to the reverse osmosis stage.The process scheme includes also an energy recovery device (R) and a booster pump.

Figure 5 – Reverse Osmosis application to produced water treatment

3. Projects and Innovation

The treatment of produced water is an hard challenge for all the major oil companies. Both Eni and Shell for the Blacktip Field (north Australia) and Auk platform, respectively, have adopted an adsorption based technology licensed from CETCO Oilfield Services which appears to be extremely effective. This type of treatment package utilizes water polishing adsorption filters which are specifically designed to remove oil, grease and soluble organics from water based streams. The adsorption media is based on resin, polymer, and clay technology.

A completely different approach has been followed in a Montana oilfield (U.S.A.) using a mobile station to design a plant to cost efficiently treat the produced water for agricultural irrigation. In this case it has been used a combination of physical and chemical treatment in order to comply with reuse and discharge limits. This mobile station consists of three stages: pretreatments, membrane filtration and post treatment. Two spiral-wound membrane units were employed and the rejections of various constituents were examined. Cost analysis showed that the treatment cost of produced water is less expensive than to dispose of it by injection. This solution may be of great value in water-poor regions [9].