Author: Giovanni Franchi-Chemical Engineer – PhD Student –University UCBM – Rome (Italy)

1.Theme Description

Energy use grew up from 4.6 Mtoe[1] in 1973 to 13.4 Mtoe in 2012.Total final energy consumption decreased in Europe while it increased in non-OECD countries, reaching a further 1.3% in 2014 (i.e China 3.1% and 4.3% in India).[2],[3]

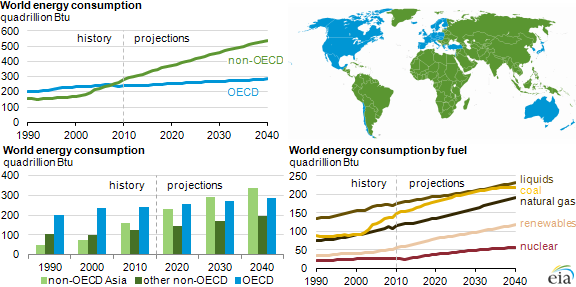

Figure 1 shows World Energy consumption for OECD and Non-OECD country from 1990 to 2040. As can be seen from 2010 up to 2040, it will grow of 56% from 524 quadrillion of BTU to 820 quadrillion of BTU. The industrial sector will consume more than 50% of the energy in 2040 and this energy will be produced for 80% from fossil fuel.

Figure 1 – World Energy Consumption from 1990 up to 2040.[4]

In this scenario Chemical and Petrochemical sectors contribute to a large part of the Industry energy consumption (~ 30% including feedstocks)[5]. Therefore, in the following section, Best Practice Technologies (BPT) that allow to save energy and reduce CO2 emissions are described.

2.Energy Consumption in Chemical and Petrochemical Sectors

The energy consumption from Industry reached 29% of final energy consumption in 2012 and Chemical and Petrochemical sectors are the largest energy users with 35 EJ[6] (see Figure 2), contributing to about 7% of the global CO2 emissions.[7]

Figure 2 – Energy consumption by sector (figure 1) and Industrial Energy Consumption by sector (figure 2) (2)

The main energy consuming processes are steam cracking, ammonia production from natural gas and coal, extraction of aromatics, methanol and butylene that accounts for about 70% of the consuming.5

The energy efficiency in these sectors has been started since 1970s after oil crisis.

Table 1 and Table 2 show some of the possible measures to increase energy efficiency. In particular, Table 1 refers to the main equipment used in the processes,while Table 2 refers the production of specific chemical compounds.

| Equipment, Steam Distribution and

Controls |

Measures to increase Energy Efficiency |

| Boiler |

|

| HeatExchanger |

|

| Steam Distribution |

|

| Electric Motors

(pump, compressor and fun) |

|

| Distillation |

|

| Control system |

|

Table 1 – Methods to Improve Energy Efficiency by referring to specific equipment (for more detail see[8],[9]).

| Chemical Compounds Production | Measures to increase Energy Efficiency |

| Ethylene |

|

| Aromatics |

|

| Polymers |

|

| Styrene |

|

Table 2 – Methods to Improve Energy Efficiency by referring to specific compounds (for more detail see 8).

2.1 Applications of Emerging Technologies

The main chemical and petrochemical processes (i.e. steam cracking, ammonia production etc.) use catalysts to enhance the velocity of specific reaction increasing the yield. The IEA in collaboration with International Council of Chemical Association (ICCA) and DECHEMA estimated that improvement of catalysts and related processes could reduce energy consumption of 20-40% in 2050.[10]

Recently new processes have been developed to produce these compounds at lower costs:

- Methanol to Olefin (MTO), uses synthetic gas instead of crude oil. UOP and Norsk Hydro (now Ineos) developed a MTO process that allows to increase the yield of ethylene and propylene reducing by-product and catalyst consumption.[11]This process has been tested at semi-commercial scale by Total Petrochemical in Belgium.

- Hydrogen Peroxide Propylene Oxide (HPPO), produces propylene oxide by the reaction of hydrogen peroxide and propylene. The process saves about 10-12% of energy (included hydrogen peroxide production) compared to conventional processes10 avoiding by-products such as propylene dichloride and styrene monomer. One of the biggest commercial plant (300,000 t/year) is in Belgium based on BASF/Dow chemical technologies.[12]

- Gas to Liquids (GTL),where natural gas is converted into liquid fuels such as naphtha, kerosene, diesel etc.[13] Nowadays there are five commercial plants developed by Shell (Malaysia and Qatar), Sasol (South Africa) and joint venture between Sasol and Chevron (Qatar). These plants have a capacity between 2,700 bbl/d up to 140,000 bbl/d and high investment costs[14] (i.e. Shell cancelled a plant in Louisiana due to the jump of the price from 12.5 to over 20 B$[15]). Therefore recently, small GTL plant shave tested. A commercial plant was realized in Brazil by Petrobras and CGTL. It produces 200,000 scf/d and it costed 45US$.[16]

2.2 Indices to evaluate Best Practice Technologies (BPT)

Nowadays two terms are used to group the most efficient technologies used in the processes:

- BPT, means Best Available Technologies and refers to most advanced technologies economically available at industrial scale.

- BAT, stands for Best Available Technologies more technologically advanced, but not always economically suitable.

In some cases, the two terms coincide. In the chemical and petrochemical sectors usually refer to BPT.5,[17]

The International Energy Agency (IEA) in the reporton: “Chemical and Petrochemical: Potential of Best Practice Technology and other measures for improving energy efficiencies” has defined two different indices for Energy Efficiency and CO2 savings.

The former is the ratio between the sum of the minimum energy associated to each process and total energy use by chemical and petrochemical processes (Table 3). The last takes into account only direct emissions excluding that related to electricity, use and waste treatments (Table 4).

The value of both indices is function of the approach used. In both top-down and bottom-up approaches the energy efficiency is the ratio the potential performance of the sector under BTP and the current performance. However, in the top-down approach the BPT values are scaled by a coverage factor set equal to 0.95 for all country. While for bottom-up approach this value is specific for each country. The coverage factor takes into account that not all processes are considered. In the table 3 are shown the results for 57 processes and 66 chemical products. Considering electricity, the improvement potentials reaches 20%.5

| Country | TFEU[18]

[PJ/y] |

(BPT)T-D[19]

[PJ/y] |

(BPT)B-U[20]

[PJ/y] |

(EEIj)T-D[21]

[%] |

(EEIj)B-U[22]

[%] |

IT-D[23]

[%] |

IB-U[24]

[%] |

| USA | 6412 | 4851 | 5713 | 75.6 | 89.1 | 24.4 | 10.9 |

| China | 4301 | 4459 | 3397 | 103.7 | 79.0 | -3.7 | 21.0 |

| Germany | 1064 | 1048 | 931 | 98.5 | 87.5 | 1.5 | 12.5 |

| India | 1096 | 1113 | 893 | 101.5 | 81.4 | -1.5 | 18.6 |

| France | 627 | 556 | 563 | 88.7 | 89.9 | 11.3 | 10.1 |

| Italy | 389 | 348 | 344 | 89.5 | 88.5 | 10.5 | 11.5 |

| World | 31,529 | 26,544 | 26,898 | 84.2 | 85.3 | 15.8 | 14.7 |

Table 3 – Improvement potentials of main Countries in 2006 (excluding electricity) (6)

The top-down approach underestimates the improving potential for China and India leading to a negative value. While bottom-up approach leads to coverage factor, for some country, more than 100%. Therefore, both methods have critical elements due to overestimation of the process. Indeed, heat cascading and co-generation are neglected.

| Country |

Direct CO2 Emissions [Mt CO2/y] |

(CO2)index-mix[25] | (CO2)index-NG[26] | ||

| T-D

[%] |

B-U

[%] |

T-D

[%] |

B-U

[%] |

||

| USA | 278 | 0.63 | 0.81 | 0.51 | 0.67 |

| China | 148 | 1.03 | 0.50 | 0.47 | 0.07 |

| Japan | 111 | 0.80 | 0.87 | 0.53 | 0.59 |

| Germany | 42 | 0.95 | 0.74 | 0.63 | 0.46 |

| France | 27 | 0.79 | 0.80 | 0.52 | 0.53 |

| Italy | 12 | 0.73 | 0.70 | 0.43 | 0.40 |

| World | 1,255 | 0.65 | 0.66 | 0.50 | 0.51 |

Table 4 – CO2 savings for main countries in 2006 (5)

The CO2 savings is equal to:

- 20-37% with the actual fuel mix and 37-57% with natural gas, for a top-down approach;

- 19-50% with actual fuel mix and 33-60% (excluding China) with natural gas for a bottom-up approach.

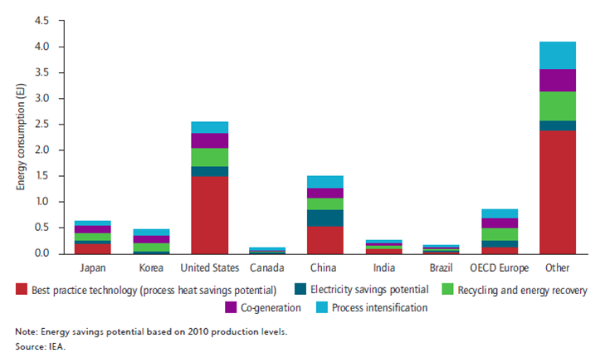

Finally, in the figure 3 is shown the energy saving potential with BPT and other options such as co-generation, recycling, energy recovery etc.For chemical and petrochemical sectors, the energy saving potential with BPT amount to 120-150 Mtoe/year and 370-470 MtCO2/year.7

Figure 3 – Comparison between energy saving potential.[27]

3.Conclusions

The Chemical and Petrochemical sectors are the largest energy users within industrial sector and they reached 30% of final consumption in 2012. There are several measures to improve energy efficiencies (Table 1 and Table 2) and some of emerging processes are Methanol to Olefin (MTO), Hydrogen Peroxide Propylene Oxide (HPPO) and Gas to Liquid (GTL). The International Energy Agency (IEA) has defined two indices to evaluate the Energy Efficiencies and CO2 potential savings by applying Best Practice Technologies (BPT). This term groups the most advanced technologies economically available at industrial scale. The value of these indices depends on the approach used: top-down or bottom-up. The two methods lead to different results but both in some cases overestimate or underestimate the improvement potential. Therefore, it is necessary to consider more data and associate BPT with co-generation, recycling energy and the use of biomass feedstocks. IEA in collaboration with International Council of Chemical Association (ICCA) and DECHEMA, also, define four pathways to be followed in the future: improve feedstock energy (i.e. production of synthetic gas from several raw material), fuel form gas and coal, New routes to polymer (i.e. saccharification of lignocellulose into bioethanol) and hydrogen production (i.e. from biomass, waste material, improve of water electrolysis etc.).[28]