Author: Marcello De Falco, Associate Professor, University UCBM – Rome (Italy)

1.Theme description

The effects on the human health and the impact on the environment due to the exposure to and the presence of heavy metals as lead, cadmium, mercury and arsenic have been extensively studied by international bodies as WHO, attesting clearly a significant negative impact also at low metals composition. Although adverse health effects have been known for a long time, the exposure to heavy metals continuously increases due to their extensive use in industry [1] (refer to Figure 1).

Fig. 1 – Global production and consumption of heavy metals during the period 1850–1990 [2]

Specifically, the soil contamination by heavy metals is particularly dangerous for humans and for the ecosystems since most metals do not undergo microbial or chemical degradation and their concentration in soils persists for a long time and it is accumulated. The main risks associated are listed as follow [3]:

- direct ingestion or contact with contaminated soil;

- food chain (soil-plant-human or soil-plant-animal-human);

- drinking of contaminated ground water;

- reduction in food quality (safety and marketability) via phytotoxicity;

- reduction in land usability for agricultural production causing food insecurity.

The soil contamination is an increasing issue for the expansion of industrial areas, disposal of high metal wastes, leaded gasoline and paints, land application of fertilizers, sewage sludge, pesticides, wastewater irrigation, coal combustion residues, spillage of petrochemicals [4].

Some technologies have been developed worldwide for the remediation of contaminated soil. The most widely applied are:

- Immobilization – organic and inorganic amendments are applied to alter the original soil metals to more geochemically stable phases via sorption, precipitation and complexation processes [5]. Among the immobilization technologies, the most used are Solidification/Stabilization and Vitrification.

- Soil Washing – it is essentially a volume reduction/waste minimization treatment process. There are two soil washing techniques: physical separation, by which the soil particles which host the majority of the contamination are physically separated from the bulk soil fractions; chemical extraction, by which contaminants are removed from the soil by aqueous chemicals and recovered from solution on a solid substrate [6].

- Photoremediation – it uses vegetation and associated microbiota and agronomic techniques to remove or contain contaminants harmless [7]. The most used technique is the Phytoextraction, i.e. the process where plant roots uptake metal contaminants from the soil to their above soil tissues.

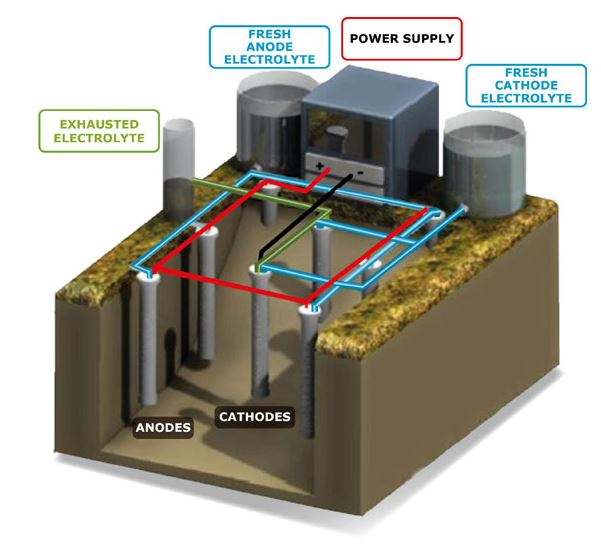

But, the most interesting technology in terms of cost, efficiency and easiness in management is the Electro-Kinetics Remediation (EKRT): an electric field is generated by two electrodes inserted into the ground and encapsulated in extraction wells and the electrically charged metal ions are transported, collected and removed from the soil (a conceptual scheme is reported in Figure 2 [8]).

Electro-Kinetics Remediation technology is known and applied since 20 years, but ENI, with the partnership of the University of Ferrara, has developed an optimized EKRT configuration for heavy metal recovery from contaminated soil, better described in the following paragraph.

Fig. 2 – EKRT functioning scheme

2. ENI’s Electro-Kinetic Remediation Technology

ENI developed an optimized EKRT able to reduce the technology costs and to improve the application easiness, mainly for large-scale use. ENI’s EKRT can be applied to remove from the contaminated soil a wide variety of metals, as Zn, Pb, As, Cd, Co, Fe, Cr, Mn, Cu, Sn.

The main innovations introduced concern:

- the reduction of the electrodes number, allowing a management simplification and a saving of 30% approx. on the final cost.

- Commercial electrodes are installed, fabricated with a new production method able to reduce their costs (50% lower than electrodes used a decade ago).

- Optimization of the electrolytic solution. The solution used by the conventional technology is aggressive and provokes a soil contamination, while the simplified electrolytic solution developed and optimized is able to mobilize the metals without a further pollution of the ground.

- Easiness of the management and control system. Thanks to the optimized electrodes configuration and to the simplified electrolytic solution, the operative control system is much easier and more robust than the conventional ones.

- The better performance of the ENI’s architecture allows a reduction of the voltages applied for the electric field generation and of the remediation time, leading to an energy saving and a reduction of operative costs.

Fig. 3 – EKRT configuration developed by ENI and University of Ferrara [9].

The major benefits can be summarized as follow:

- In-situ treatment;

- High efficiency in terms of pollutant removal;

- It does not require heavy interventions of soil handling (with the exception of the electrode installation), no excavations and/or transportation of polluted material;

- High level of environmental sustainability and social acceptability;

- Improved performance than similar solutions on the market;

- Lower investment costs and lower operating costs (savings up to 50%);

- Simple management;

- All the installed equipment can be re-used;

- wide range of applicability since the technology can be used to remove various metals as Zn, Pb, As, Cd, Co, Fe, Cr, Mn, Cu, Sn by simply varying applied voltage, application time and electrolytic solution.

3.Application and state-of-the-art

ENI has performed EKRT experimental tests on site using real soils. Both the single metal (Hg) and a more complex (many metals) decontamination applications have been assessed, with very promising results in terms of recovery efficiency and operative easiness.

In the following some images, taken from the ENI website, show the electrodes installation and the experimental phases.

Fig. 4 – EKRT electrode installed on-site

Fig. 5 – Electrodes distancing

Fig. 6 – Experimental tests

ENI patented the EKRT solution (patent application n° MI2012A001889), and the patent approval is in progress.